RFID key fobs have replaced plastic smart cards. They are more convenient, stronger, and more functional. Despite the fact that these ID devices have been on the market for a long time, they are still popular with customers. Lear more about how we make such key fobs and what we take into account when producing them.

What is an RFID key fob?

An RFID key fob is a contactless ID device. It is made from PVC plastic and coated with a special resin. A radio frequency tag is installed inside the key fob, which is necessary for identification in various systems.

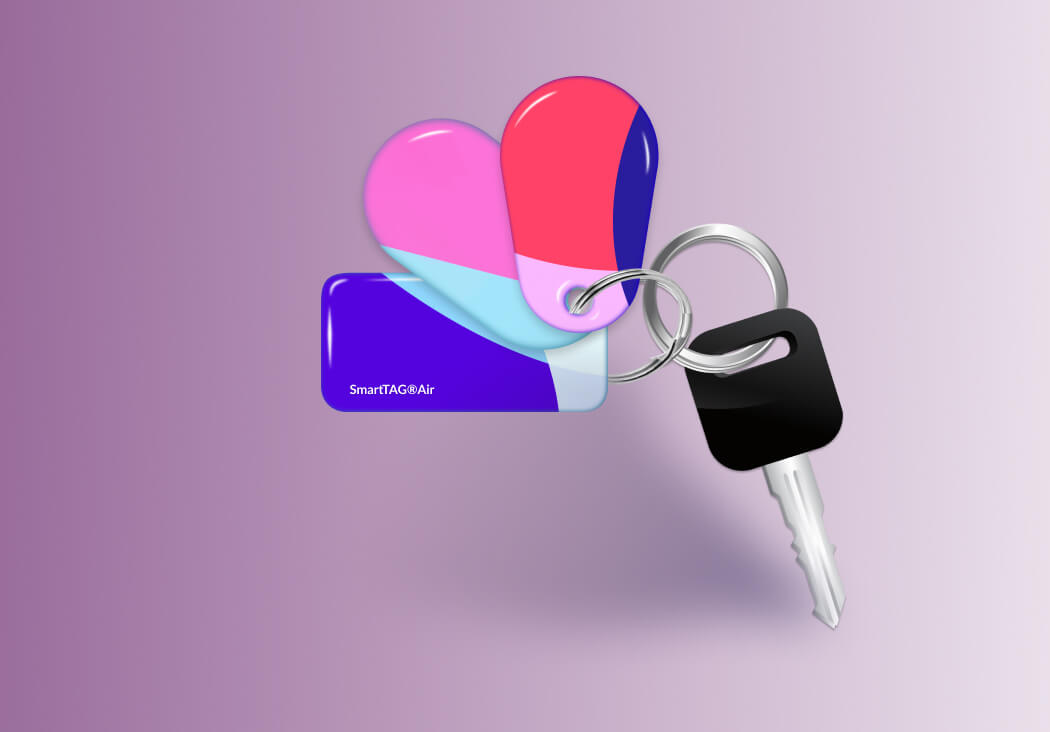

We supply key fobs of three various design types: rectangular, teardrop and oval. All of them have a streamlined shape, thanks to which they do not cling to anything or interfere. Each SMARTTAG® RFID key fob has a hole that can be used to attach it to keys, a bag, etc. This hole is positioned in such a way as not to damage the tag and antenna installed inside.

All our key fobs can be printed in full color. You can order a layout from our designers or provide us with your own one. We manufacture our key fobs on European equipment, which ensures crisp prints, accurate color reproduction and vivid shades. The polyurethane resin coating adds volume and creates a more presentable appearance.

What are key fobs made from?

Like plastic cards, RFID key fobs consist of several separate layers. They are manufactured on the same equipment. Manufacturing process has several stages.

- First, the inner layer is created, to which the tag and antenna are attached.

- Then the central pre-laminated layer is formed. The inner layer sheet is placed between two plastic sheets, then all layers are joined together using a thermocompression method.

- Before the layers are bonded together, and the base is made, the front and back key fob sides are printed on the advanced European equipment. The offset printing method guarantees high image detail and clarity, which is especially important for small images printed on key fobs. Then all layers are bonded together: the pre-laminated layer is placed between the front side and the back side. We add two sheets of protective laminate. All sheets are cured together. The preset temperature ensures reliable bonding of all layers. Therefore, plastic RFID key fobs can serve for quite a long time.

- Then key fobs are cut out from the multilayer plastic sheets. Each key fob has a special ring hole used to attach it to keys or a bag. The hole is sized and positioned so as not to damage the tag and antenna inside. That is why we strongly recommend not to make additional holes in the ready-made key fobs.

- The last stage of production includes coating the blanks with resin. It is first applied to one side of the SMARTTAG® key fob. It takes 4 to 6 hours for the polymer coating to cure. Then the resin is applied to the other side, after which it is cured for another 4-6 hours. During the curing process, the coating adheres firmly to the plastic. Therefore, it does not peel off or break off from the key fob.

What chips are used in SMARTTAG® key fobs?

SMARTTAG® RFID key fobs have the same chips as smart cards. We offer a wide choice of ultra high frequency (840-960 MHz), high frequency (13.56 MHz) and low frequency (125 kHz) chips supplied by original manufacturers: NXP Semiconductors, EM Microelectronic-Matine, Fudan, Temic (Atmel), HID and many others.

All our RFID tags comply with ISO 14443, ISO 15693, ISO18000, and ISO11784/ISO11785. All our chips are reliably protected from counterfeiting, but some of them provide a higher level of security. We recommend to choose a chip model based on the required protection and functionality.

Our chips operate stably in all conditions. Besides, they perform all the required functions to successfully replace RFID cards.

What material is the protective coating made of?

RFID key fobs are often coated with epoxy resin. However, this material has a large number of drawbacks:

- the coating often peels off and cracks

- scratches, cracks and dents appear rather quickly

- epoxy resin turns yellow under UV rays, and the colors fade

- the attachment point becomes brittle, and the key fob becomes easy to lose

All this affects the performance and appearance of key fobs. Moreover, epoxy resin is toxic. Since RFID key fobs are generally used every day, this can be rather hazardous to health.

Therefore, we only use polyurethane resin. It is non-toxic and safe. This coating is hypoallergenic, and even children can use our SMARTTAG® key fobs. Nothing dangerous will happen if your child or pet accidentally bites a key fob.

The polyurethane resin adheres very firmly to the key fob surface and does not flake off even with active use. Besides, it has a self-healing effect, which makes small scratches and dents gradually disappear. Your key fob will look as good as new for a very long time. The coating acts as a lens, making the image on the RFID key fob look more voluminous and bright. A certain layer thickness is required to get such effect. The viscosity and temperature of the material are pre-selected depending on this.

The polyurethane resin can be mixed with various additives, such as colorants, fragrances, etc. The antibacterial additive is also used in the formula. Once all these agents are added to the resin, it becomes resistant to dirt and UV rays.

Thus, the polyurethane coating protects key fobs against the following factors:

- breakage (a key fob is impossible to bend, it can withstand a weight of more than half a ton),

- dirt (including scratches and dents),

- ultraviolet radiation (the coating does not turn yellow, and the colors remain bright for a long time).

What advantages do SMARTTAG® key fobs have?

Electronic key fobs replace standard contactless cards. They perform the same functions, but they are much more convenient. The SMARTTAG® key fobs are small enough to fit in any pocket. Besides, if you attach the key fob to your backpack, keys or clothes, it will be impossible to lose or mislay.

Unlike smart cards, key fobs are very strong and durable. It is impossible to break with bare hands, because it can withstand the pressure of more than half a ton. Polyurethane resin protects the key fob from adverse environments, including water, high and low temperatures, etc. Therefore, it can be used even under extreme weather conditions.

Reliable ergonomic design with bright full color printing will delight any owner.